Goal

- Explore the possibilities of the Uni Pro Kit

- use it for housings and frames

- maybe even for a little device or rig

Action items

- build alternative housing / frame for the Nimble™

- do the construction with FreeCAD utilizing the UPKLib

- expore the toolchain

- automatic BOM in FreeCAD

- assembly guide (step by step exploded views)

- integrating 3D-PCBs from KiCAD

- how to represent cable-trees

People and their roles

| Name | Role |

|---|---|

| Oliver Schlüter | UPK Introduction, Maintainer |

| Jason Selvarajan | Prototyping Nimble case with UPK + some 3d printing for testing |

| Marcel Partap | Documentation |

Documentation

Universal Prototyping Kit for

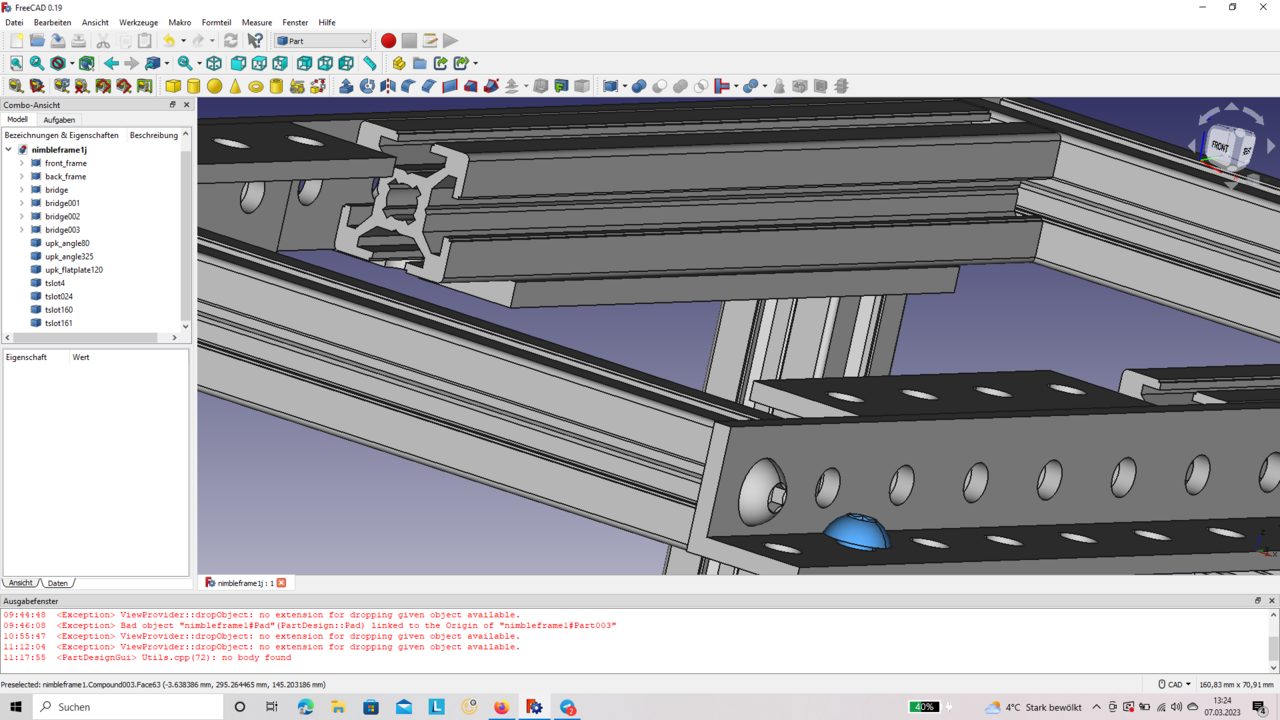

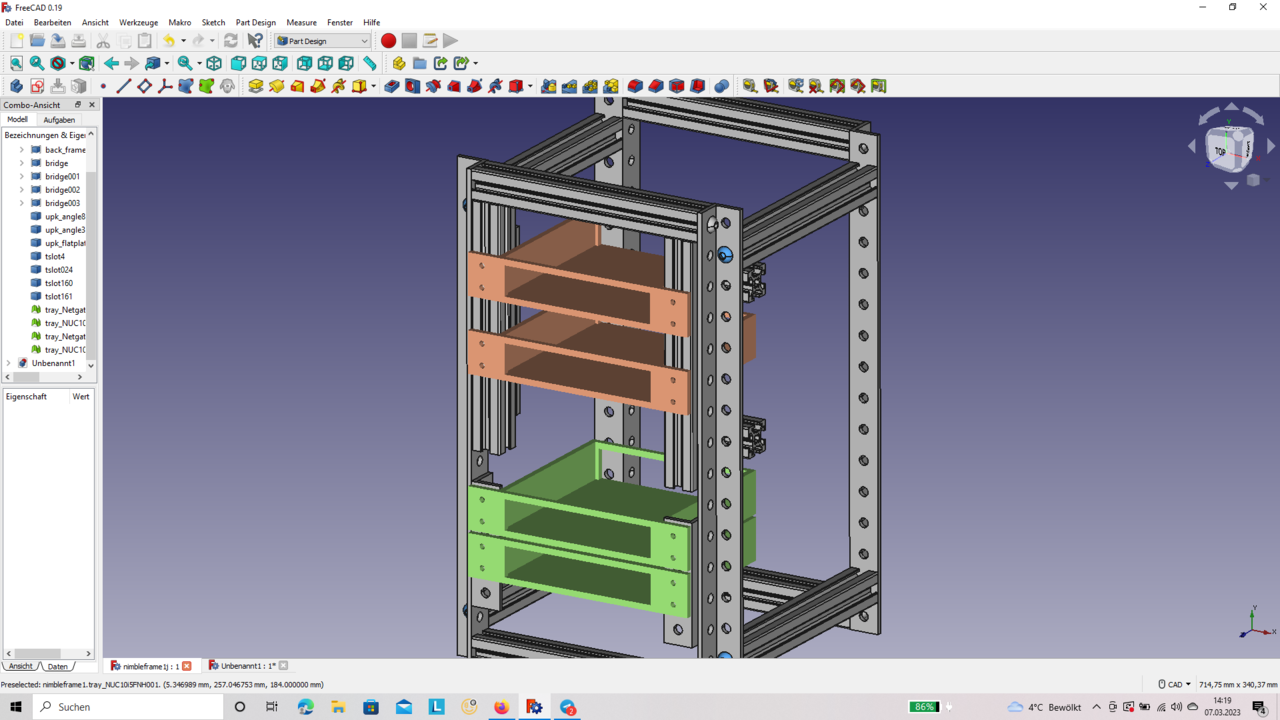

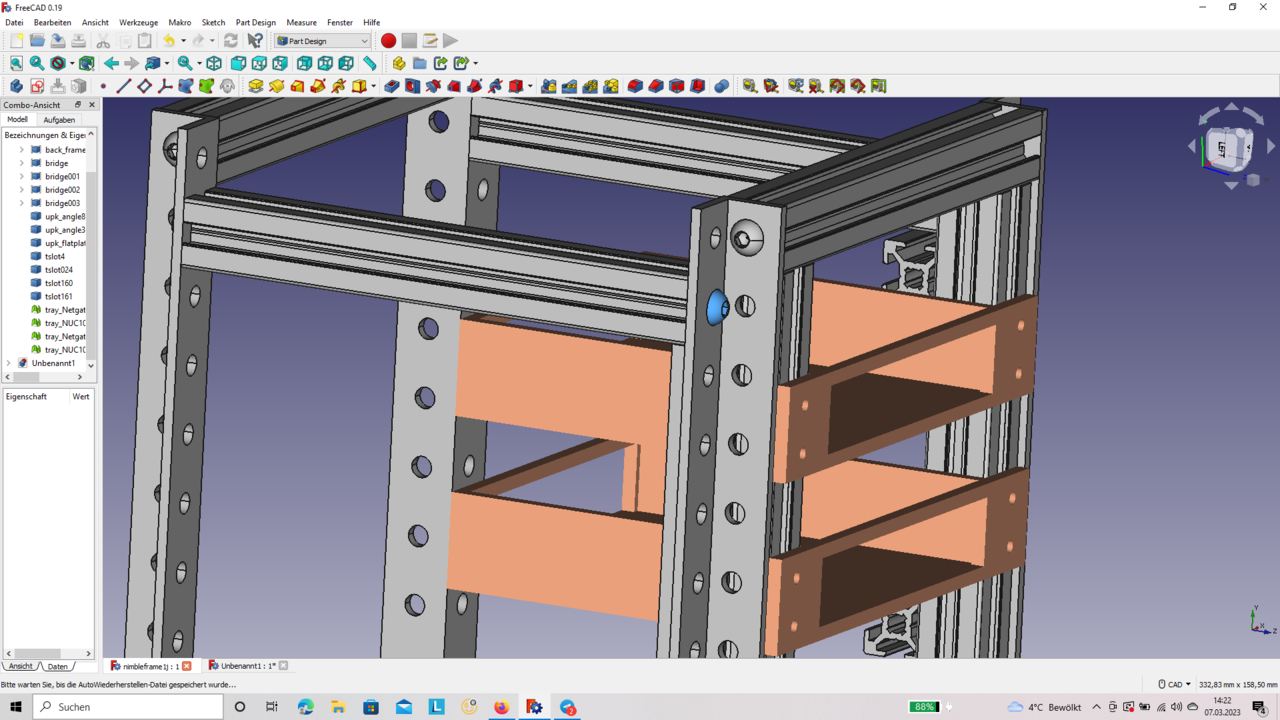

- We built a prototype frame from UPK case for Nimble to fit into a waterproof case (some Pelican clone from Italy).

- The UPK uses 20 mm as a grid size while Nimble is around 14 mm so it took a little bit of tricks to get them to fit together.

The UPK frame inside the box, still needs some fixing points and ‘buffers/dampening’ to keep it safe during travels.

The UPK frame inside the box, still needs some fixing points and ‘buffers/dampening’ to keep it safe during travels.  Here’s an example to some MacGuyvering, where the T-slot on the bottom is adjustable and allows the perpendicular T-slot to rest ontop of it. This T-slot is fixed to the racks, which isn’t perfect, but allows for the racks to be removed from the box in a pretty simple way.

Here’s an example to some MacGuyvering, where the T-slot on the bottom is adjustable and allows the perpendicular T-slot to rest ontop of it. This T-slot is fixed to the racks, which isn’t perfect, but allows for the racks to be removed from the box in a pretty simple way.

The parametric racks would make it even faster and easier.

Summary

Results

What did you accomplish?

We made a prototype alternative frame for Nimble using UPK. It still requires 3d-printed frames for the electronic housings, so in a way, all we did was replace the 14mm plastic T-frame clone with the real one. The benefit is that it’s a bit more rhobust/weather proof and can help make the assembly much faster - assuming the parts haven’t been printed in advance.

Next steps

What needs do be done after this hackathon?

- Finish the freecad 3D model and assembly instructions.

- Make it look as good as Nimble.

Open questions

UPK seems to be good for rapid prototyping but the parts are (relatively) expensive to be used permanently compared to ABS/PETG or alternatives like wood or sheet metal. So is this a viable solution, even though it looks cool?

Links

Issue tickets etc.